In a previous post about the sometimes ambiguous meaning of the word “caliber”, we discussed how the word had mutated through the centuries, picking up different definitions and connotations along the way. In that article, I wrote:

So “caliber” has gone from meaning the mold used to create a bullet, to a system of nomenclature indicating imprecisely both the capabilities and the interchangeability (or lack thereof) of different kinds of ammunition, and the weapons that fire them. Indeed, now, the word “caliber” more often refers to the name of a given cartridge-rifle system than it does any physical quality of either, for example the .223 Remington caliber is not named after any specific measurement on the bullet (0.224″), case, or bore (0.219″), but simply so-named to differentiate it from other similarly-named calibers!

If “caliber” can refer to a weapon-ammunition system, then what is a weapon-ammunition system, exactly? Also, what are the challenges that face military ammunition engineers when trying to develop part of, or even a whole, ammunition system for service?

A firearm is a machine, but its purpose isn’t just to discharge once then be done, rather to be able to shoot many many times. To accomplish this, the weapon (which is the actual gun itself) needs to accept ammunition (which is the expendable material needed to fire), and for that to happen, the ammunition needs to physically fit in the firearm first, and then not destroy the firearm when discharged. Since, for cartridge firing weapons, ammunition and firearm both must be made separately, this means a system is needed to ensure that the firearm is able to shoot over and over again, without exploding, and while having the desired effects on the target. For military ammunition, accomplishing even these basic tasks consistently enough to conduct military operations is a huge challenge. Ammunition must not only interact with the weapon to create the desired effects and without causing it damage, but it also must be durable, environmentally stable, and have a long shelf life. Military small arms ammunition must – for example – be able to sit in a humid warehouse for 20 years and still be ready to be dropped out of an airplane to troops who will then as a matter of course mishandle it until they need it to work exactly right when they need it, in any environment, all over the globe.

This post concerns military ammunition primarily, but so that we can better understand what an ammunition system is, we’ll take first the simplest real-world example we have: A custom target rifle shooting handloads. A weapon like this places the least demands on the weapon-ammunition system, because:

- Only one actual weapon is in the system,

- The ammunition is being handloaded by the user, who is intimately familiar with the weapon used in the system, and

- The desired effects on the target are minimal (punching paper, ringing steel, etc) and require only one type of projectile.

Because there is only one weapon in the system and only one type of projectile is needed, the rifle’s chamber and barrel can be perfectly optimized for the kind of projectile being fired. Throat dimensions, rifling twist rate, etc can all be perfectly tweaked to achieve maximum performance with the most efficient possible projectile. Likewise, the ammunition itself can be perfectly tuned to the rifle; cases can be sorted for uniformity, necks can be turned down on a lathe to perfectly match the rifle’s chamber dimensions, propellant can be selected and loaded to perfect density and with the ideal burn rate, and even the primers can be selected for the most consistent and efficient ignition characteristics. In other words, because of the simplicity of the system (one individual rifle, one purpose, hand-selected components), the ballistic performance of the system overall can be pushed to their very limits.

Some of the huge variety of US military .30 caliber (better known as .30-06) rounds used during its service life. The projectiles fired by each of these rounds differ substantially in length, construction, center of mass, and other important characteristics that influence how they fly. Image source: Wolfganggross, used with permission and edited for appearance by the author.

Military weapon-ammunition systems are far more complicated, and therefore must compromise absolute ballistic performance to work. Instead of one host weapon, there are potentially hundreds of thousands, or even millions of firearms in the system, in multiple styles and varieties that often differ mechanically. Instead of perfectly tuned, handcrafted ammunition, these weapons must be able to shoot any selection of the billions of rounds produced per year to feed the war machine. Instead of one kind of carefully selected projectile and one variety of propellant and primer, there are several potentially very different kinds of projectiles designed for different purposes, and often a requirement to work using multiple different kinds of primers and propellants, as well. Worse, even with all of these different elements in the system, the ammunition must meet rigid and extremely thorough acceptance standards for velocity, dispersion, pressure, and the rest of a whole host of incredibly detailed requirements, and all of the variety of weapons in that caliber used by the services must function reliably with all kinds of ammunition. All this means that military ammunition systems are several orders of magnitude more complex than the example above. Because of this, some ideas that work in the civilian world or the laboratory do not work very well in military use, or have significant downsides.

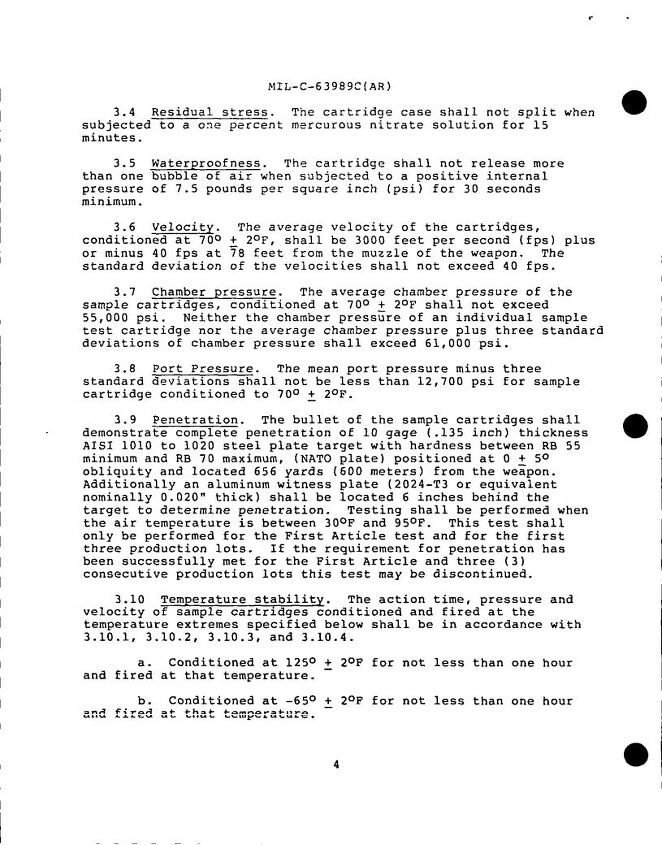

This is just one page out of 27 from the specification document for the 5.56mm M855 round, which itself is just one out of over 14 different kinds of US military standard rounds that can be fired from all weapons in 5.56x45mm NATO caliber.

To fully understand how hard it is to create a successful military ammunition system, or even just a part of one, we’ll need a little more meat to chew on, so let’s look at a hypothetical example based on real-world ammunition development:

It’s these kinds of challenges that make ammunition development a truly difficult task that requires a lot of time and money.

Because the system must work well with these different kinds of ammunition which are each made in vast quantities, the characteristics of one kind of round can affect the entire caliber system, and potentially promising new developments that do not conform to the existing system may have to be discarded. For example, it is important for the point of impact of a weapon to remain essentially the same regardless of the ammunition type being used (although for practical reasons this can only be accomplished to a certain degree). If a new round is created that performs better than current ammunition when it hits the target, but which has a substantially different point of impact than the existing ammunition in the system, it will likely not be adopted, regardless of the improvement in performance. There simply isn’t much point to issuing a round that will miss when the sights are set for the standard issue round!

Likewise, when developing a new kind of ammunition, compromises sometimes must be made because of other rounds that will be a part of the system. A special projectile like armor piercing or tracer that uses a different and/or longer shape due to stability or internal volume requirements might end up having more drag than a shapelier ball round, meaning that the latter would have to be “nerfed” during development and made draggier to match the trajectory of the specialty projectiles. Another common problem is projectiles types that may be an excellent idea in theory but which have problems that in practice make them unusable. We can see this problem in long, low drag projectiles which stabilize well at high velocities in temperate or hot climates, but which are not stable when fired at lower velocity due to cold climates or extensive barrel wear. In this event, the barrel twist rate must either be shortened (made tighter) to ensure stabilization, or the projectiles made more stable somehow (usually by making them shorter). Indeed, a great deal of styles and types of projectiles and ammunition that in theory look excellent are in practice infeasible for one reason or another.

Example after example of how caliber systems are developed for and by military departments are available in the excellent three-volume series History of Modern U.S. Military Small Arms Ammunition, by Hackley, Woodin, and Scranton, which details with a un-embellished thoroughness the journey of US small arms ammunition from 1880 to 1977 (ending with the closure of Frankford Arsenal). In these three volumes you’ll find examples of hundreds, if not thousands of failed ammunition ideas that seemed like such a good idea at the time, but that proved unfeasible or undesirable in the end. Given that military development is not generally concerned with curiosity for its own sake, many of the good-idea-ending problems that are detailed in the pages of History are never resolved or even fully understood, leaving those threads hanging for the next development program to pick up.

We can describe the development of military cartridge systems as a sort of careful juggling act: Each element has to not only work by itself, but together with the rest of the elements in the system (In fact, each element has to play nice with elements of other systems, too, something that from time to time causes serious problems in military weapon development*). The end result of this juggling act is a series of different weapons and ammunition that, taken individually, may seem shockingly imperfect or suboptimal, but which together act and function successfully as a combined system of millions of different weapons and hundreds of billions of rounds of ammunition of various types.

*This is also why the .300 Blackout will never as such be adopted by the US military. The intercompatibility problem with 5.56mm and the substantial risk of explosion makes it simply unsuitable for any military service (besides very, very elite groups) currently using weapons in that chambering.

Your Privacy Choices

Your Privacy Choices