News

SpaceX execs bullish on BFR as Mars rocket test facilities expand in Texas [photos]

Aerial observations of SpaceX’s McGregor, Texas testing facilities on April 17 revealed an unusually frenetic level of construction and expansion centered around Raptor – the rocket engine intended to power BFR and SpaceX to Mars – and a new test-stand, the purpose of which is currently unknown.

With a minimum of 1200 seconds of hot-fires under its belt, SpaceX’s Raptor propulsion program is likely rapidly approaching the end of what is best described as the experimental phase of testing. While this has not been communicated by SpaceX, it is a logical conclusion following several recent developments. Namely the true beginning of BFR test article fabrication and an impressively bullish level of commitment and confidence in the fully reusable launch system demonstrated in the last few months alone by CEO Elon Musk and President/COO Gwynne Shotwell. While Musk is infamous both within and beyond his companies for painfully impractical development timelines, he demonstrated some level of growing consciousness of that fallibility at 2018’s SXSW, stating that he was working on recalibrating his expectations. Without taking a breath, he reiterated his anticipation for short hop tests of the first full-scale spaceship prototype in the first half of 2019.

SpaceX’s three-bay Raptor test stand as of April 17. The middle bay is currently home to the subscale Raptor test program. (Aero Photo)

While anyone familiar with Musk’s timeline antics may roll their eyes and laugh, far more shocking was Shotwell’s sudden pivot towards a new sense of optimism for the BFR program. At Satellite Conference 2018, the typically reserved and pragmatic executive confirmed beyond any doubt that she had become aggressively bullish on the Mars rocket, stating that she believed the spaceship would be ready for suborbital testing in 2019, while the booster-spaceship system could potentially reach orbit by 2020. Musk and Shotwell’s suggestion that BFR’s first suborbital testing – akin to an extreme version of SpaceX’s Grasshopper and F9R programs – is expected to begin in 2019 meshes well with a recent explosion of activity at Port of San Pedro in Los Angeles, CA, thanks to a combination of land acquisition, successful bureaucracy-wrangling, and the first hints of construction and BFR production. It’s highly unlikely that SpaceX would have chosen to temporarily move BFR prototyping into a giant tent on abandoned dock space rather than waiting for port and city approvals for their permanent port factory if they were not keen on moving full speed ahead with the fully reusable launch vehicle’s development.

SpaceX has completed over 1,200 seconds of firing across 42 main Raptor engine tests. pic.twitter.com/EhxbPjd8Cj

— SpaceX (@SpaceX) September 29, 2017

SpaceX’s Director of Real-Estate Bruce McHugh was less confident when he spoke before Port of San Pedro’s board of commissioners on April 19, although all in attendance expressed a huge amount of excitement at the increasingly likely prospects of a huge SpaceX rocket factory materializing in their neighborhood. Local contractors, economic development representatives, and many other community members were eager for the approval and permitting process to finish up, after which SpaceX is characteristically likely to begin demolition and construction in earnest at Berth 240, the prospective site for the company’s first dedicated BFR factory.

Early phases of in-house BFR structures prototyping is taking shape behind the flaps of a custom-ordered temporary tent, something like 60m long, 30m wide, and ~15m tall at the highest point – half an acre of eccentric but functional space for Mars rocket R&D, in other words. The primary benefit of these facilities’ dock-side locations is the minimization of the transportation hell that SpaceX would have had to suffer through to transport 9m-diameter rocket hardware through downtown Los Angeles – feats that would cost as much as $2.5 million one way each time components had to be moved from the Hawthorne factory to the Port of LA, where it would be finally shipped to Texas or Florida.

- SpaceX’s first major BFR and BFS fabrication tooling, likely being stored temporarily in a tent at Port of San Pedro. Note the tent framework at the top. (Elon Musk)

- Just a casual line of car-sized steel segments hanging around outside the BFR tent. (Pauline Acalin)

- It’s understood that SpaceX will eventually move this work to Berth 240 once more permanent facilities are constructed. (Pauline Acalin)

- SpaceX’s BFR tent and mandrel, caught on April 14th. (Pauline Acalin)

Speaking at a private talk given to MIT campus members in October 2017, attendees reported that Shotwell stated that although “[BFR’s] composite tanks [would] be a challenge [for SpaceX],” the company was already working on maturing the technologies required, and also noted that SpaceX was “building a larger [version of] Raptor right now.” Half a year later, outsiders have heard nothing of any additional carbon composite propellant tank testing at the new 9m diameter, but the existence of custom-ordered (i.e. very expensive and specialized) composite fabrication tooling of the same diameter as BFR effectively guarantees that SpaceX has settled upon and is confident in its approach to manufacturing the massive composite tankage and structures. Along with a similar line of thought, expensive tooling with a fixed diameter also indicates – albeit with less certainty – that the vehicle’s Raptor propulsion system is not expected to change significantly as BFR marches closer to suborbital and orbital testing. Raptor, in other words, is probably considerably more mature than SpaceX’s composite tankage expertise, itself fairly advanced given the mandrel and additional fabrication tooling already present at Port of San Pedro.

And yet, Shotwell’s most telling display of confidence occurred just a handful of days ago at the TED2018 conference. In a lengthy and fairly well-orchestrated interview with the session’s host Chris Anderson, Shotwell repeatedly and happily made comments indicating that she has become extremely bullish on BFR and BFS in the last several months. In her opinion, BFR (and point-to-point Earth transport) will be deployed “within a decade, for sure.” Prices would nominally be “between business and economy,” or a few thousand dollars per person. Speaking on the trip from Earth to Mars, she estimated a three-month journey with BFR Block 1, “but [SpaceX is] gonna try to do it faster.” She further confirmed that SpaceX intends to build much larger BFRs, meshing with Elon’s suggestions that 2016’s ITS concept is now perceived internally as a sort of BFR Block 2. Perhaps most importantly, she qualified her timeline estimates as “Gwynne-time” when Anderson jokingly deadpanned about the infamous Elon-time. Overall, Shotwell came across as more bullish than she has ever been before on BFR’s development and future prospects, including both point-to-point transport on Earth and crewed missions to the surface of Mars – both of which she expected to begin “within a decade, for sure.” Smirking, she quipped that she was “sure Elon would want us to go faster.”

- BFR heads to orbit in an updated overview of the Mars rocket. (SpaceX)

- Note the 2017/early-2018 variant’s single delta-wing and extendable leg pods (silver). (SpaceX)

- According to Hans Koenigsmann, this vision may actually be incompatible if NASA and the US government are given too much control. (SpaceX)

Not one to end on a quiet note, the typically pragmatic executive finished by describing how she believed that spreading human presence throughout the Sol System was only “the first step [towards] moving to other solar systems and potentially other galaxies; I think this is the only time I ever out-vision Elon.” Interstellar travel and faster-than-light propulsion aspirations aside, Shotwell’s comments mark a fairly incredible shift in attitude toward SpaceX’s far loftier ambitions. Musk seems to be working to recalibrate his timelines to be less naive at the same time as Shotwell’s confidence is steadily growing – the two executives, in other words, appear to be rapidly converging upon a middle ground of pragmatic optimism (that or Musk-time is contagious!).

- Raptor’s McGregor, TX engine test bays are seen here in April 2018. A subscale Raptor prototype is visible in the center bay. (Aero Photo/Teslarati)

- A new rocket test-stand takes shape at SpaceX’s McGregor, TX facilities. As of just a few months ago, this site was effectively barren of activity. (April 17, Aero Photo)

- SpaceX’s Merlin 1D (Vacuum and Sea Level) tests stands, as well as a bay for upper stage static fires. (April 17, 2018 – Aero Photo)

As shown above, the level of construction activity at SpaceX’s Texas testing facilities is fairly impressive and could perhaps be seen as evidence that both Musk and Shotwell are speaking from a place of something approaching pragmatism. While the purpose of the new stand (center) is not yet clear, several aspects indicate that it is unlikely to be more mundane. First, the massive water tower (one that did not exist just a month or two ago, might I add) dwarfs anything found at individual engine or upper stage test stands at the SpaceX facility. It’s possible that the existence of the flame trench alone necessitates the inclusion of such a large water suppression system for damage prevention, but the presence of the blue steel skeleton of a new flame bucket (operational iterations shown on the right) suggests otherwise. For example, the Merlin stands have no such water suppression system: they do use water suppression to avoid damaging the ground systems or the engines themselves, but that water is stored in a large ground-level tank. A tower, however, indicates that SpaceX wants much higher water pressures and flow rates to be available at the new stand, a requirement for significantly more powerful tests akin to SpaceX’s full-up Falcon 9 (and Heavy) test stand – the water towers at the S1 stand and this new stand appear to be identical in size.

In other words, it’s more probable than not that this new stand is being built to support either booster static fires or much larger tests of BFR hardware (perhaps multiple Raptors at once, akin to SpaceX’s very early tests of Falcon 9’s nine Merlins). It could, of course, be used for many different tasks, but only time will tell. Given the sheer level of physical progress made in the BFR program and the swelling confidence of Musk and Shotwell, I certainly know where I’d hedge my bets.

Follow us for more live updates, behind-the-scenes sneak peeks, and a sea of beautiful photos from our East and West coast photographers.

Teslarati – Instagram – Twitter

Tom Cross – Twitter

Pauline Acalin – Twitter

Eric Ralph – Twitter

News

Tesla Robotaxi just got a big benefit from the U.S. government

The NHTSA is looking to help streamline the application process for companies developing driverless vehicles.

Tesla Robotaxi just got a big benefit from the U.S. Government, as the National Highway Traffic Safety Administration (NHTSA) is looking to ease some rules and streamline the application process that could hinder the development and licensing of autonomous vehicles.

Tesla is set to launch its Robotaxi platform in the coming days or weeks, but regulation on autonomous vehicles is incredibly slim, so automakers are left in a strange limbo as permissions to operate are usually up to local jurisdictions.

The NHTSA still has the ultimate say, but it is now adopting a new strategy that will see companies gain an exemption from federal safety standards and streamline the entire application process.

The agency is authorized to grant exemptions to permit manufacturers to produce vehicles over a two or three-year period that might not comply with certain Federal Motor Vehicle Safety Standards (FMVSS). Robotaxi, for example, will eventually not have a steering wheel or pedals, through the Cybercab that Tesla unveiled last October.

The exemption program the NHTSA announced today would be possible through Part 555 of the National Traffic and Motor Vehicle Safety Act:

“NHTSA may grant a Part 555 exemption if at least one of four bases listed in the statute is met and NHTSA determines that the exemption is consistent with the public interest and the Safety Act. The statute also authorizes NHTSA to subject an exemption to terms the agency deems appropriate and requires that NHTSA publish notice of the application and provide an opportunity to comment.”

The rapid and non-stop innovation that is being performed is tough to keep up with from a legal standpoint. The NHTSA recognizes this and says current legislation is appropriate for traditional vehicles, but not for the self-driving cars companies are producing now:

“The current Part 555 process was designed for traditional vehicles. As currently applied, this process is not well suited for processing exemptions involving ADS-equipped vehicles in a timely manner or overseeing the unique complexities involving their operations. This has resulted in long processing times for applications for ADS-equipped vehicles. NHTSA must improve its Part 555 processing times substantially to keep pace with the rapid innovation of the ADS industry and to ensure that exemptions remain effective tools for nurturing groundbreaking safety technologies.”

Now, the NHTSA will be “enhancing application instructions” to help manufacturers understand the requirements involved in the application process. This will streamline the entire process by “reducing the need for NHTSA to request additional information from the manufacturer,” the agency says.

First Tesla driverless robotaxi spotted in the wild in Austin, TX

Next, the NHTSA is going to have a more flexible approach to evaluating exemptions for ADS-equipped vehicles:

“To build flexibility into the Part 555 process while also accounting for the unique aspects of those exemptions, NHTSA intends to develop terms that could be included in Part 555 exemption grants, when appropriate, to condition operations of exempted ADS-equipped vehicles on enhanced and continuing oversight from NHTSA. NHTSA would expect to administer this enhanced oversight through letters, which could be updated over time, mirroring real-world ADS development. This will enable NHTSA to focus its initial review during the application stage and align the Part 555 oversight approach more closely to exemptions administered under NHTSA’s Automated Vehicle Exemption Program (AVEP), which have proven effective for ADS.”

This will benefit any company making autonomous vehicles, but it will especially benefit Tesla in the short-term as it is readying for the launch of Robotaxi.

Tesla is trading up 1.89 percent at the time of publication.

Part 555 Letter June 2025 by Joey Klender on Scribd

News

SpaceX produces its 10 millionth Starlink kit

The first 5 million Starlink kits took nearly four years to build.

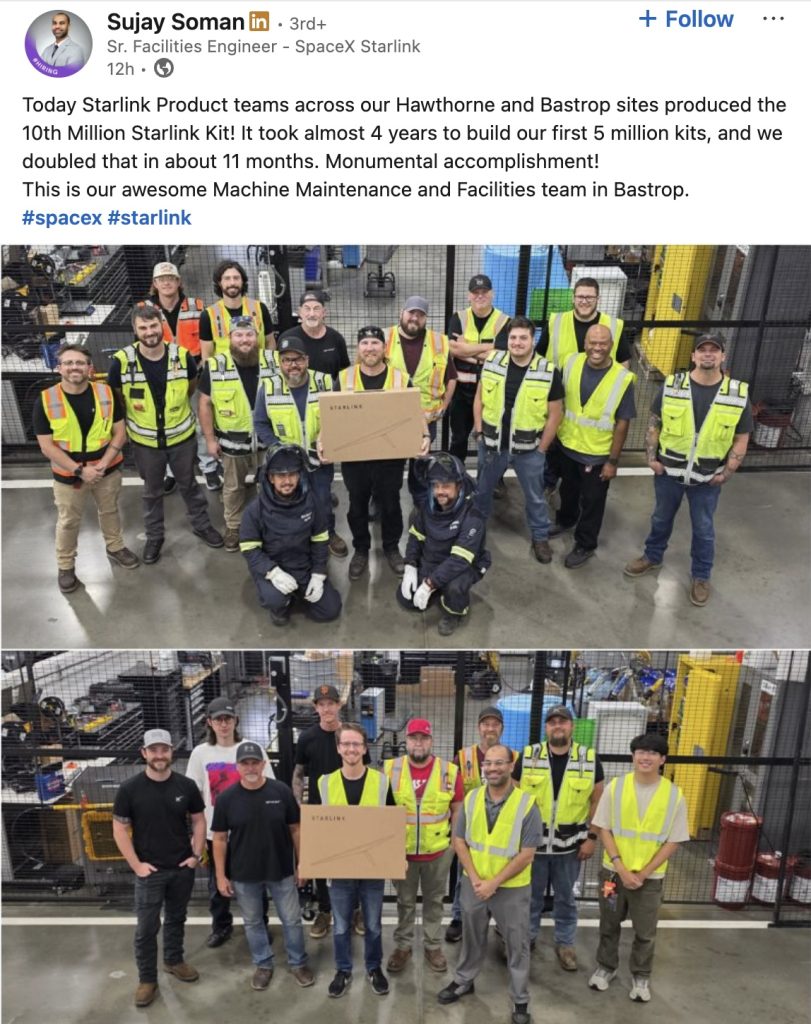

SpaceX has achieved a major milestone, producing its 10 millionth Starlink kit. The accomplishment was celebrated across the company’s Hawthorne, California, and Bastrop, Texas, facilities.

The milestone was shared in social media by Sujay Soman, Senior Facilities Engineer, in a LinkedIn post, which has since been deleted.

Starlink Production Ramp

Soman noted in his LinkedIn post that the first 5 million Starlink kits took nearly four years to build, but the next 5 million kits were completed in just 11 months. This underscores SpaceX’s intense efforts to ramp up the satellite internet system’s production, and it reflects the private space company’s manufacturing prowess.

The SpaceX Senior Facilities Engineer shared a couple of photos of the Machine Maintenance and Facilities team in Bastrop to commemorate the event.

“Today, Starlink Product teams across our Hawthorne and Bastrop sites produced the 10th Million Starlink Kit! It took almost 4 years to build our first 5 million kits, and we doubled that in about 11 months. Monumental accomplishment!” Soman wrote in his post.

World-Changing Technology

The Starlink kits, featuring dish hardware and supporting equipment, enable users to connect to the company’s growing constellation of low Earth orbit satellites. With over 6,000 satellites launched to date, Starlink now provides fast and reliable internet connectivity to over 6 million customers worldwide. This was a significant increase from the 5 million customers that the company reported in February 2025.

SpaceX has not detailed its next production targets, but the production of Starlink’s 10 millionth kit milestone signals the company’s readiness to scale further. Being an Elon Musk-led company, SpaceX is arguably the best in the business when it comes to efficient and cost-effective manufacturing. It would then be unsurprising if SpaceX announces another Starlink production milestone soon.

News

Tesla retires yoke steering wheel in base Model S and X

Tesla’s controversial steering yoke is now exclusive to the Model S and Model X Plaid.

Tesla has closed a chapter in the saga of the Model S and Model X’s controversial steering yoke. Following the announcement of the new iterations of the flagship vehicles, Tesla promptly removed the steering option for the vehicles’ base variants.

This means that if drivers wish to experience the Model S or Model X with a yoke, they would have to go Plaid.

The new Model S and Model X

The refresh of the Model S and Model X were quite minor, with the two vehicles featuring a new front camera, a new color, and a handful of other small changes like new exterior styling for the Model S Plaid. Tesla also noted on its website that the two vehicles now have a much smoother and quieter ride.

The changes were quite polarizing, with some appreciating the subtle improvements made to the two flagship cars and others arguing that Tesla should have done more. Others, however, noted that the level of improvements implemented on the Model S and Model X would already be considered major refresh for a tech company like Apple.

No More Yoke Unless Plaid

When Tesla refreshed the Model S and Model X in 2021, the vehicles were released with a steering yoke as standard. The yoke was controversial, with critics stating that it was unsafe and fans stating that it made driving the Model S and Model X fun. Tesla later introduced a round steering wheel option for the Model S and Model X, which later became standard on the two flagship vehicles.

This remains true today, with the most recent versions of the Model S and Model X still being released with a round steering wheel as standard. Those who wish to experience the Model S and Model X Plaid as envisioned by the company and its CEO, Elon Musk, however, might find it a good idea to spend the extra $1,000 for the vehicles’ yoke steering wheel.

-

News2 weeks ago

News2 weeks agoTesla to lose 64 Superchargers on New Jersey Turnpike in controversial decision

-

News4 days ago

News4 days agoI took a Tesla Cybertruck weekend Demo Drive – Here’s what I learned

-

Elon Musk1 week ago

Elon Musk1 week agoElon Musk explains Tesla’s domestic battery strategy

-

News2 weeks ago

News2 weeks agoTesla’s apparent affordable model zips around Fremont test track

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla stock: Morgan Stanley says eVTOL is calling Elon Musk for new chapter

-

Elon Musk4 days ago

Elon Musk4 days agoTesla tops Cathie Wood’s stock picks, predicts $2,600 surge

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks agoTesla bull writes cautious note on Robotaxi launch: ‘Keep expectations well contained’

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoElon Musk responds to Tesla Supercharger shutdown on NJ Turnpike