SpaceX

SpaceX will build and launch Starship/Super Heavy in Texas and Florida, says Musk

According to SpaceX CEO Elon Musk, the company has plans to both build and launch BFR’s Starship upper stages and Super Heavy boosters at facilities located in Boca Chica, Texas and Cape Canaveral, Florida.

Indicative of SpaceX and Musk’s rapidly evolving plans for the next-generation, ultra-reusable launch system, the to stainless steel over carbon composites appears to continue to have a range of trickle-down consequences (or benefits) throughout the rocket’s design, production, launch, and operations. Given the 3+ radical, clean-sheet design changes the BFR program has undergone in about as many years, it’s hard to definitively conclude much about the latest iteration. Nevertheless, Musk’s indication that stainless steel BFRs may now be built simultaneously at multiple locations suggests that the construction of steel Starships and Super Heavies could be radically easier (and cheaper) than their composite predecessors.

Over the last several months, SpaceX’s manufacturing plans for the massive Starship and Super Heavy vehicles have effectively been up in the air from a public perspective. Official statements provided in January suggested that the first prototypes would be built in-situ after word broke that SpaceX had prematurely terminated a lease with the Port of Los Angeles, where the company had – throughout 2018 – been planning to construct a dedicated seaside BFR factory.

Likely for a variety of reasons, all of which are unknown, SpaceX apparently no longer has a pressing need for dedicated traditional manufacturing facilities at this point in time. Instead, the company is relying extensively on the largely unprecedented practice of building its first suborbital and orbital Starship and Super Heavy vehicles outdoors, much to the visible discomfort of aerospace industry practitioners, followers, and fans alike.

At a bare minimum, SpaceX’s decision to fabricate and assemble large-scale methalox rocket stages with quite literally zero protection from the elements may be one of the most ‘nontraditional’ things the habitually disruptive company has ever done. At the opposite end of the spectrum, building rockets outside could be perceived as an unfathomably foolish endeavor, radically increasing the risk of dangerous manufacturing defects, foreign objects debris (FOD) mitigation, and – ultimately – major vehicle failures. From such an external perspective, wholly lacking any insight from SpaceX itself, it’s difficult to conclude much of anything.

On the one hand, a highly-disciplined adherence to the tenets of best aerospace industry practices and responsible engineering could probably mitigate the risks of en

Given that the production of orbital-class, super-heavy lift rockets has really only been attempted twice (Saturn V and Russia’s N1), both times with custom-built, environmentally-controlled factories, it’s likely that SpaceX is already suffering from the inherent uncertainty of the tasks at hand; forging new ground – especially in highly technical fields – is rarely easy or forgiving. Given the aforementioned challenges of building large and reliable rockets at all, challenges that regularly topple vehicles built in traditional factories, it will likely remain an open question if SpaceX can consistently build reliable, technologically-advanced rockets and spacecraft outside until those vehicles have quite literally proven themselves in orbit.

Toot Toot! Hopper is chomping at the bit today!

?@BocaChicaGal https://t.co/0ZEXcKOWwH pic.twitter.com/PEm7c12KTi— Chris B – NSF (@NASASpaceflight) March 18, 2019

Difficulties aside, it’s easy to understand why SpaceX (or maybe just Elon) is willing to at least attempt something that has never been done before. If the company could find a way to reliably build complex, high-performance rockets without the need for expensive factories, it could radically change the paradigm of rocketry by reducing the often eye-watering upfront costs of building giant launch vehicles. The ability to build rockets almost independently of dedicated factories or assembly facilities would also allow SpaceX to – as Musk said – build their vehicles where they launch, further minimizing the significant challenges and costs of transporting extremely large structures more than a couple of miles.

Regardless of the major challenges standing between SpaceX and its stainless steel Starship/Super Heavy aspirations, Elon Musk appears to be as confident as ever, frankly stating that Starship’s rate of progress “far exceeds” that of Falcon and Dragon. In other words, the apparent instability of the BFR program may actually end up being to its benefit, potentially resulting in a finished product that simultaneously takes less time to come to fruition and is ultimately much closer to its original design intent. At risk of putting the wrong words into Musk’s mouth, it seems that he believes that SpaceX might be able to arrive at a Starship/Super Heavy combo much closer to Falcon 9 Block 5 than Falcon 9 V1.0 and do so far sooner than most believe is possible.

Only time will tell. In the meantime, there will be plenty of fireworks, beginning as early as this week with the first static fire test – and potential hops – of SpaceX’s massive Starship Hopper. Stay tuned for updates!

Check out Teslarati’s Marketplace! We offer Tesla accessories, including for the Tesla Cybertruck and Tesla Model 3.

News

Starlink makes a difference in Philippine province ravaged by typhoon

The Severe Tropical Storm battered the province, leaving communications networks in the area in shambles.

The Philippines’ Department of Information and Communications Technology (DICT) is using Starlink to provide connectivity in the municipality of Masbate, which was affected by Severe Tropical Storm Opong (international name Bualoi).

The Severe Tropical Storm battered the province, leaving communications networks in the area in shambles.

Starlink units enhance connectivity

DICT Secretary Henry Aguda visited the province to assess internet and communications infrastructure and deliver 10 additional Starlink satellite units, according to the Philippine News Agency. The is move aimed at strengthening emergency response and restore digital access to the area.

Aguda met with Masbate Governor Richard Kho during his visit and joined telecommunications representatives in inspecting provincial offices, free charging stations, and Wi-Fi connectivity sites for residents.

According to DICT officer-in-charge Rachel Ann Grabador, three Starlink units, 10 routers, and a 2kW solar-powered station have already been deployed in the province following the typhoon. The units have been installed at key facilities such as Masbate Airport’s communications tower and the Masbate Provincial Hospital’s administrative office.

Game-changing technology

Thanks to its global coverage and its capability to provide high-speed internet connectivity even in remote areas, Starlink has become the best communications solution that can be deployed in the aftermath of natural disasters. Its low-cost kits, which are capable of of providing fast internet speeds, are also portable, making them easy to deploy in areas that are damaged by natural disasters.

As noted in a Space.com report, there are currently 8,475 Starlink satellites in orbit, of which 8,460 are working, as of September 25, 2025. Initially, SpaceX had filed documents with International regulators to place about 4,000 Starlink satellites in Low Earth Orbit. Over time, however, the number of planned Starlink satellites has grown, with SpaceX aiming to launch as many as 42,000 Starlink satellites to fully connect the globe.

Elon Musk

SpaceX shares targets and tentative launch date for Starship Flight 11

As with all SpaceX tests, the estimated timeline for Starship Flight 11 remains subject to change based on conditions and readiness.

SpaceX is targeting Monday, October 13, for the eleventh test flight of its Starship launch system. The launch window is expected to open at 6:15 p.m. CT.

Similar to past Starship missions, a live webcast will begin about 30 minutes before launch on SpaceX’s website, X account, and X TV app. As with all SpaceX tests, the estimated timeline for Starship Flight 11 remains subject to change based on conditions and readiness.

Super Heavy booster landing test

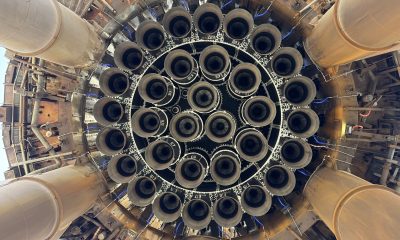

The upcoming mission will build on the data gathered from Starship’s tenth test flight, focusing on booster performance and upper-stage capabilities. The Super Heavy booster, previously flown on Flight 8, will launch with 24 flight-proven Raptor engines, according to SpaceX in a blog post on its official website. Its primary objective is to validate a new landing burn engine configuration designed for the next generation of Super Heavy.

Instead of returning to Starbase, the Super Heavy booster will follow a trajectory toward the Gulf of America. During descent, it will ignite 13 engines before transitioning to a five-engine divert phase and then completing the landing burn with three central engines, entering a full hover while still above the ocean surface, followed by shutdown and dropping into the Gulf of America.

Starship upper-stage experiments

The Starship upper stage for Flight 11 will carry out a series of in-space demonstrations, including the deployment of eight Starlink simulators that are comparable in size to next-generation Starlink satellites. These payloads will reenter and burn up during descent. A planned Raptor engine relight in orbit will also provide valuable test data.

To evaluate the upper stage’s resilience during reentry, SpaceX engineers have intentionally removed heat shield tiles from select areas to stress-test Starship’s thermal protection system. The vehicle will attempt new maneuvers during descent, including a banking profile and subsonic guidance algorithms intended to simulate future return-to-launch-site missions. The upper stage will ultimately target a splashdown in the Indian Ocean.

SpaceX has already posted a link to the livestream for Starship Flight 11:

News

Astra CEO shades SpaceX over employee workload and Starbase

Elon Musk once stated that no one ever changed the world working just 40 hours a week.

Elon Musk once stated that no one ever changed the world working just 40 hours a week. This was something that is openly known among his companies. They have the potential to change the world, but they require a lot of hours.

SpaceX’s working environment was recently criticized by Chris Kemp, the chief executive officer of Astra. During some remarks at the Berkeley Space Symposium 2025 earlier this month, Kemp shared some sharp remarks about the Elon Musk-led private space enterprise.

SpaceX working conditions and Starbase

As noted in a report from Ars Technica, Kemp discussed a variety of topics during his talk. These included Astra’s successes and failures, as well as his thoughts on other players in the spaceflight industry. To be fair to Kemp, he practically shaded every major rival, calling Firefly’s engine “garbage,” dubbing Blue Origin as slow, and stating that Rocket Lab’s Electron rocket is “too small.”

SpaceX also received some colorful words from the Astra CEO. According to Kemp, SpaceX is leading the way in the spaceflight industry and Elon Musk is admirable in the way that he is willing to fail in order to move quickly. He did, however, highlight that Astra offers a significantly better working environment than SpaceX.

“It’s more fun than SpaceX, because we’re not on the border of Mexico where they’ll chop your head off if you accidentally take a left turn. And you don’t have to live in a trailer. And we don’t make you work six and a half days a week, 12 hours a day. It’s appreciated if you do, but not required,” Kemp said.

Elon Musk’s demands

It is known that Elon Musk demands quite a lot from his employees. However, it is also known that Musk-led companies move very fast and, in more ways than one, they have accomplished world-changing feats. Tesla, for example, has practically ushered in the era of the modern electric vehicle, and SpaceX has made space attainable through its reusable rockets. With this in mind, employees at Musk’s companies, and this of course includes SpaceX, are likely proud of their long work hours.

No one could probably go to Mars in this lifetime with a team that really works just 40 hours a week, after all.

-

Elon Musk2 weeks ago

Elon Musk2 weeks agoTesla FSD V14 set for early wide release next week: Elon Musk

-

News2 weeks ago

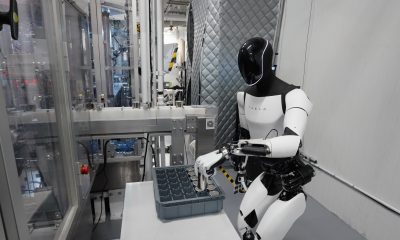

News2 weeks agoElon Musk gives update on Tesla Optimus progress

-

News2 weeks ago

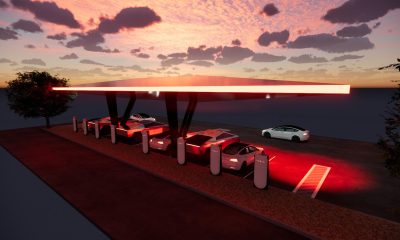

News2 weeks agoTesla has a new first with its Supercharger network

-

News2 weeks ago

News2 weeks agoTesla job postings seem to show next surprise market entry

-

Investor's Corner2 weeks ago

Investor's Corner2 weeks agoTesla gets new Street-high price target with high hopes for autonomy domination

-

Lifestyle2 weeks ago

Lifestyle2 weeks ago500-mile test proves why Tesla Model Y still humiliates rivals in Europe

-

News1 week ago

News1 week agoTesla Giga Berlin’s water consumption has achieved the unthinkable

-

Lifestyle2 weeks ago

Lifestyle2 weeks agoTesla Model S Plaid battles China’s 1500 hp monster Nurburgring monster, with surprising results