A Moonwalk Did Not Destroy Neil Armstrong’s Spacesuit. Now Time Won’t Either

Conservators are bringing new innovations to save the 80-pound suit that allowed the first astronaut on the moon to take that giant leap

:focal(683x156:684x157)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/68/83/688389d3-1e37-475a-80ab-384df67bc5c2/a19730040000cp15.jpg)

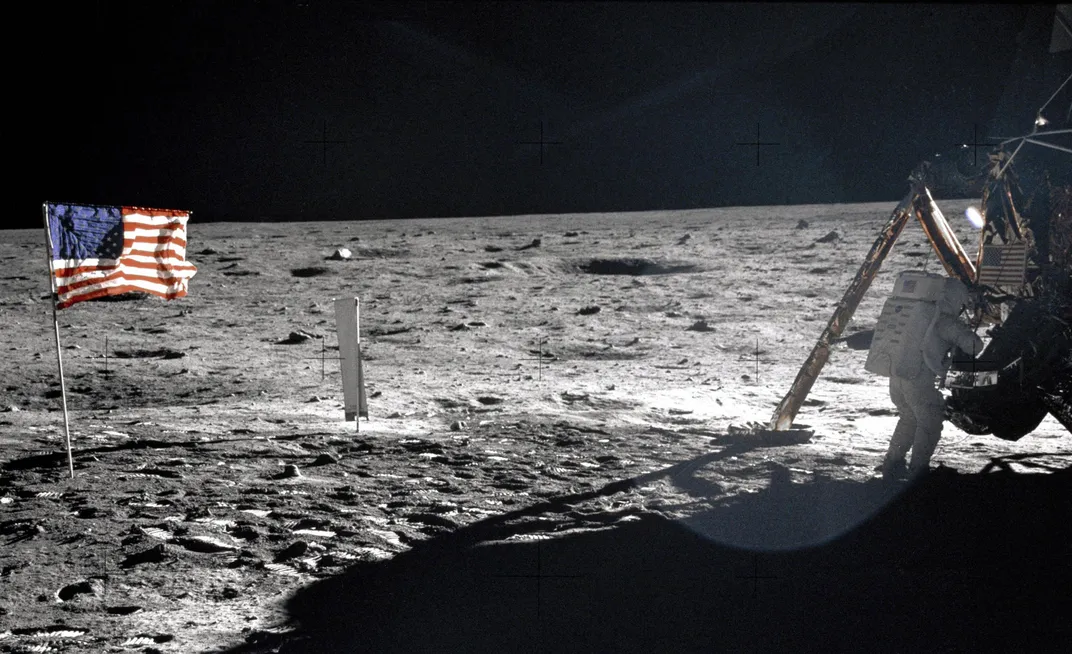

In 2019, the Smithsonian’s National Air and Space Museum will herald one of the crowning achievements of America’s space mission—the first human steps ever taken on the moon—with the display of the pressure suit, helmet and gloves worn by Neil Armstrong, the astronaut who famously said, "One small step for man, one giant leap for mankind,” as he set his boots down on the lunar surface on July 20, 1969.

But first, the Smithsonian’s curators and exhibition experts have a raft of technical hurdles. They are grappling with not only how to preserve the 80-pound suit’s 21 layers, but also how to position it in an upright and lifelike position. Their work—which is getting under way in earnest—is being fueled in part by the Smithsonian’s first Kickstarter campaign in 2015 that raised $719,779 to be spent on the Armstrong suit’s conservation and display.

The astronauts who piloted the Apollo 11 mission to the moon and back in 1969—Armstrong, Buzz Aldrin, and Michael Collins—became national icons. Armstrong’s suit was chosen ahead of the others because “it was the first human-made object that allowed humans to explore another world,” says Cathleen Lewis, the Air and Space Museum’s curator for aeronautics.

The suit is no stranger to the public. The National Aeronautics and Space Administration (NASA) took it and the other accoutrements of the Apollo 11 mission, including the command module, on a tour between 1970 and 1971, visiting every state’s capital and the District of Columbia. Armstrong’s suit—given to the Smithsonian by NASA—then went on display in the Arts and Industries Building, and was moved to the newly opened Air and Space Museum in 1976, where it remained on display until 2006.

Armstrong’s gloves and helmet went on view briefly after his death in 2012, at the museum’s vast Steven F. Udvar-Hazy Center in Chantilly, Virginia, which opened in 2011.

But the curators knew they were racing against time. The suit’s synthetic textiles were degrading due to age and the environment, and the materials were off-gassing, contributing to the decay. Plus, spacesuits such as Armstrong’s “weren’t designed with the idea that anybody was going to come back and use it 50 years later,” says Adam Bradshaw, an exhibits specialist at the museum.

In fact, the Armstrong suit had a life expectancy of about six months, says Lewis. During the 1970s NASA tour and while on earlier display at the Smithsonian, the suit was propped up using a mannequin. This was not ideal, as the suit could fold in on itself or tear. Over the decades, gravity caused a collapse of the layers. Curators are trying to determine which damage occurred during the suit's working lifetime and which was caused by later degredation.

By the time the suit came off the museum floor in 2006, Air and Space Museum conservator Lisa Young had done the research determining the best state-of-the-art storage conditions. An archival box kept at a steady 60 degrees Fahrenheit and 30 percent humidity became the new home for Armstrong's suit. Those conditions were later replicated in a large walk-in cooler at the Udvar-Hazy Center. That cooler now contains the Armstrong suit and some 270 other spacesuits and 1,000 related artifacts, says Lewis.

“We’ve learned a lot in the last 45 years,” she says. Curators now know that visible light and ultraviolet radiation can have a cumulative effect on textiles, which has led to a lowering of light in the storage area. They also have customized mannequins so they do not damage the materials.

The Armstrong team is leading efforts to build custom mannequins but they also have talked with a variety of experts—from engineers on the original Apollo 11 “suiting team” at Kennedy Space Center to materials specialists at DuPont, which created the special fabrics, to the managers on the suit’s sewing team—some of whom are still alive—at the suit's manufacturer, ILC Dover. The Armstrong curatorial team has also consulted with modern textile manufacturers, and curators and exhibitions specialists at the Smithsonian’s National Museum of the American Indian, which has also struggled with displaying delicate textiles, and the Victoria and Albert Museum in London, among others.

The Armstrong suit was different than its predecessors because it had to be flexible enough for walking, says Lewis. In previous missions, astronauts were sitting in a capsule or floating in space. That lower body flexibility has proven to be a challenge. The suit, kept in cold storage and lying down flat, can be mostly held to its current shape relatively benignly with mannequin forms of closed cell polyethylene foam, which is chemically inert and non-abrasive.

But standing it up—with the helmet mounted on top, as if Armstrong is walking on the moon, taking his measurements and making his collections, as he did on that day in 1969—is a unique task, especially since the suit has developed wrinkles and slumps and stiff spots, over the years.

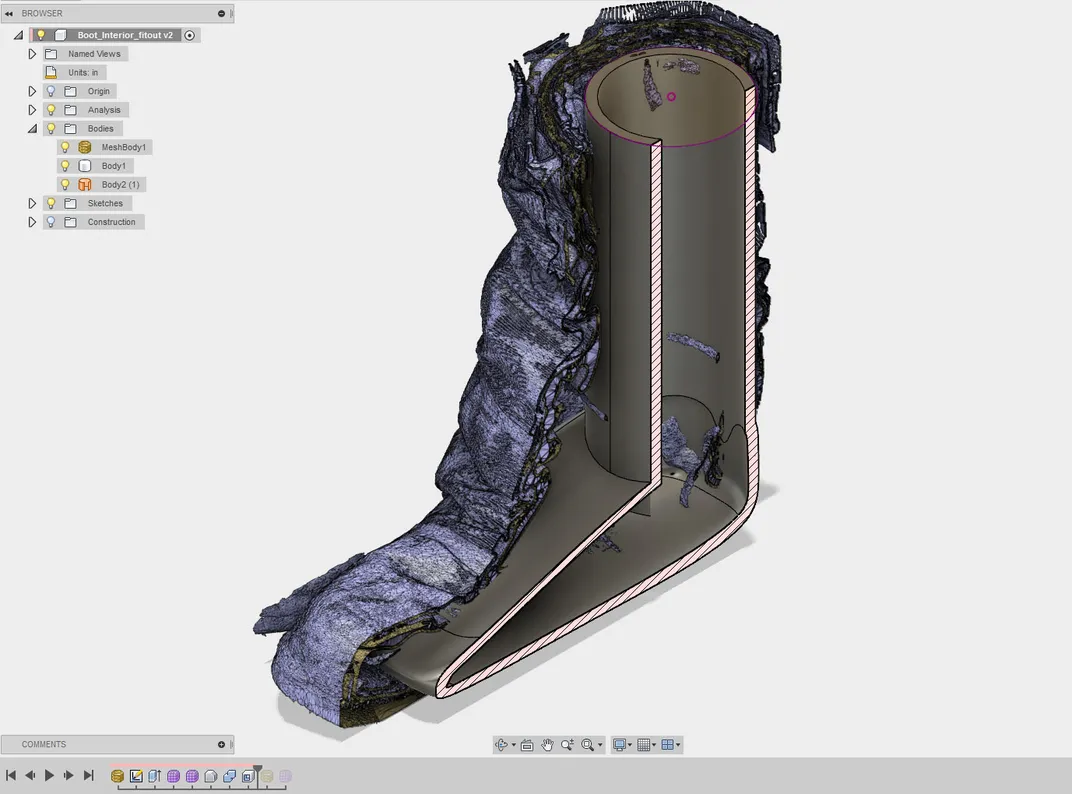

To minimize further damage—say, by shoving in ill-fitting foam inserts—curators need to know every nook and cranny. Given its delicate state, they did not want to reach into it and grope around. The only openings are from the neck and a very small hole in the waist. Instead, the curators rolled the suit into a computed tomography (CT) scanner and gathered the most explicit details—from the inside out.

That data was used to construct three-dimensional pictures of each and every aspect of the suit. Just as if it were a full-body CT scan of a human, curators can look at slices of the suit, or create models of particular sections, visualizing the boot, for instance, in three dimensions. In turn, Bradshaw, the exhibits specialist, is creating models of the suit using computer-assisted design (CAD).

“This gives me a good idea of the relative size, and relative volume of whatever type of system or structure we’re going to try to create in there,” he says.

Bradshaw is aiming to create something that fills out the suit and that can be easily manipulated from the outside—so that “we don’t have to go inside of it with screwdrivers and hex keys and ratchet sets. We can just have these parts that are more pushbutton,” he says. He’d also like to find a way to pump in fresh air and pump out the noxious gasses produced by the materials.

As a start, Bradshaw has designed polyethylene foam inserts—that, using the CAD system, can be precisely cut with a laser to match the interior spaces. Those might be able to be controlled externally with a simple pulley system, which will be fabricated using a 3D printer and laser cutting, he says. Bradshaw is also exploring a prosthetic-type device that could be inserted into the otherwise unreachable areas of the suit. For the inside of the boots, for instance, he’s testing an “expandable foot.”

This fall, he’ll start making prototypes of that foot using a 3D printer. “A lot of times you won’t know something doesn’t work until you try it,” says Bradshaw. The 3D printer will speed up the trial and error process because changes can be made relatively simply in the computer design, and then new prototypes are available faster.

While Bradshaw determines how to display the Armstrong suit without damaging it, Lewis and Young are getting started on ways to best protect the materials.

The suit withstood the mission, two weeks of quarantine, a thorough dry-cleaning, the NASA tour and the years of Smithsonian display. However, not only is it showing signs of wear, but it is considered one of the most delicate items in the Air and Space Museum’s collection, says Lewis. Repairs were made at various points, also—and those are the subject of intense research by the curators, she says. It’s not known when or why or how the repairs were made.

The suit is also still covered in lunar dust, called regolith, from the knees down—despite NASA’s cleaning and the years of non-climate-controlled exposure. “Lunar regolith is very aggressive,” says Lewis, noting that the fine powdery substance “cannot be shaken off, and cannot be dry-cleaned off.”

Microscopic examinations reveal that the regolith has embedded itself not only into the outer layer fibers, but also into the high chromium stainless steel fabric that covers the gloves and the boots. But the curators are not trying to eliminate the dust—it’s part of the realistic preservation.

When the suit goes back on display, the dust will be visible, bringing the public that much closer to that moment nearly a half-century ago that captured the globe’s imagination, when some 500 million television viewers watched Armstrong take his first steps on the moon.

“We are hoping to recapture that moment for our visitors,” says Lewis.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/AliciaAult_1.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/66/58/665891c7-98a9-4d48-a836-5e56f996637c/boot.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c7/04/c70498d5-a3a6-4885-bbe2-d9ea65fc6202/l1090294.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/AliciaAult_1.png)